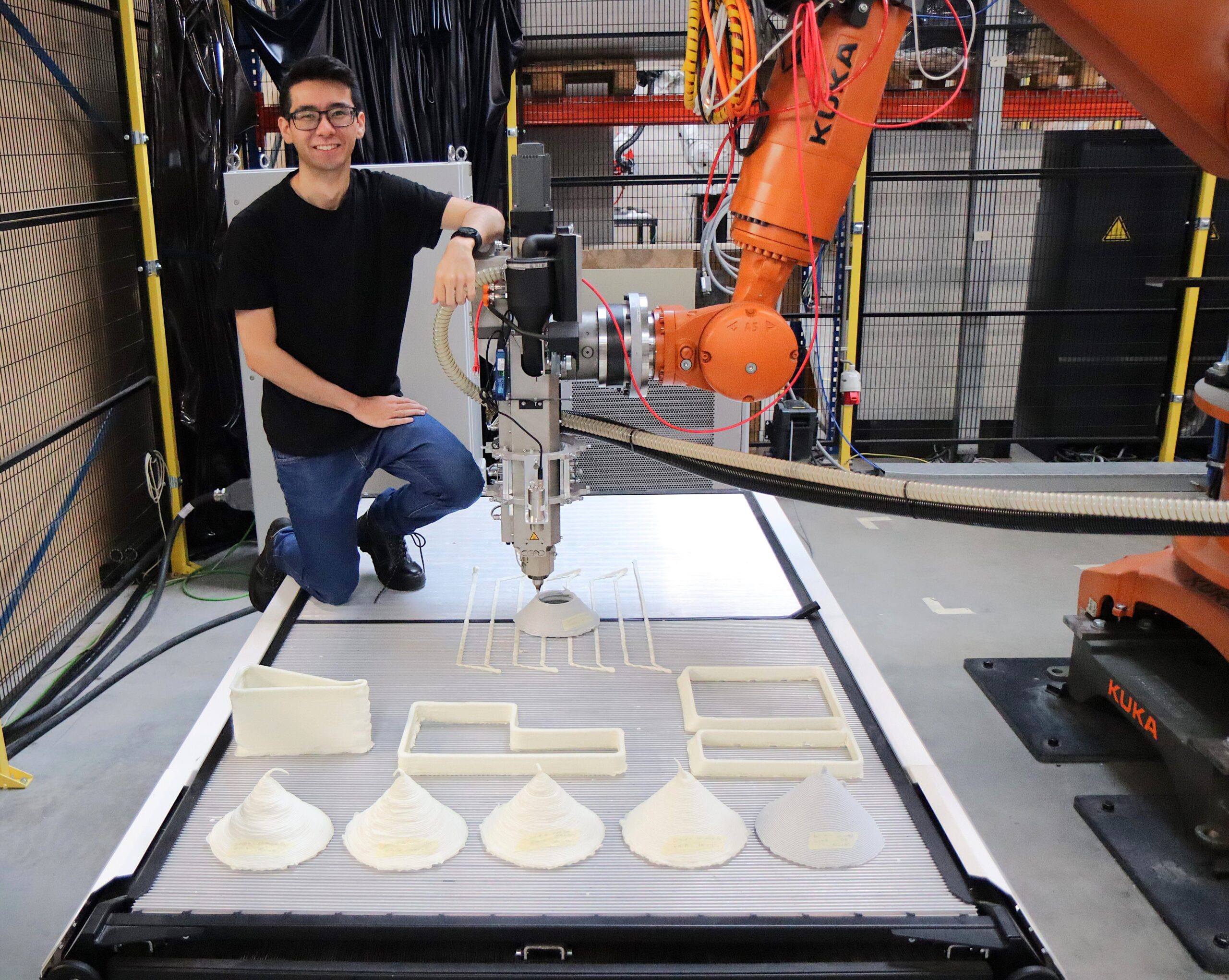

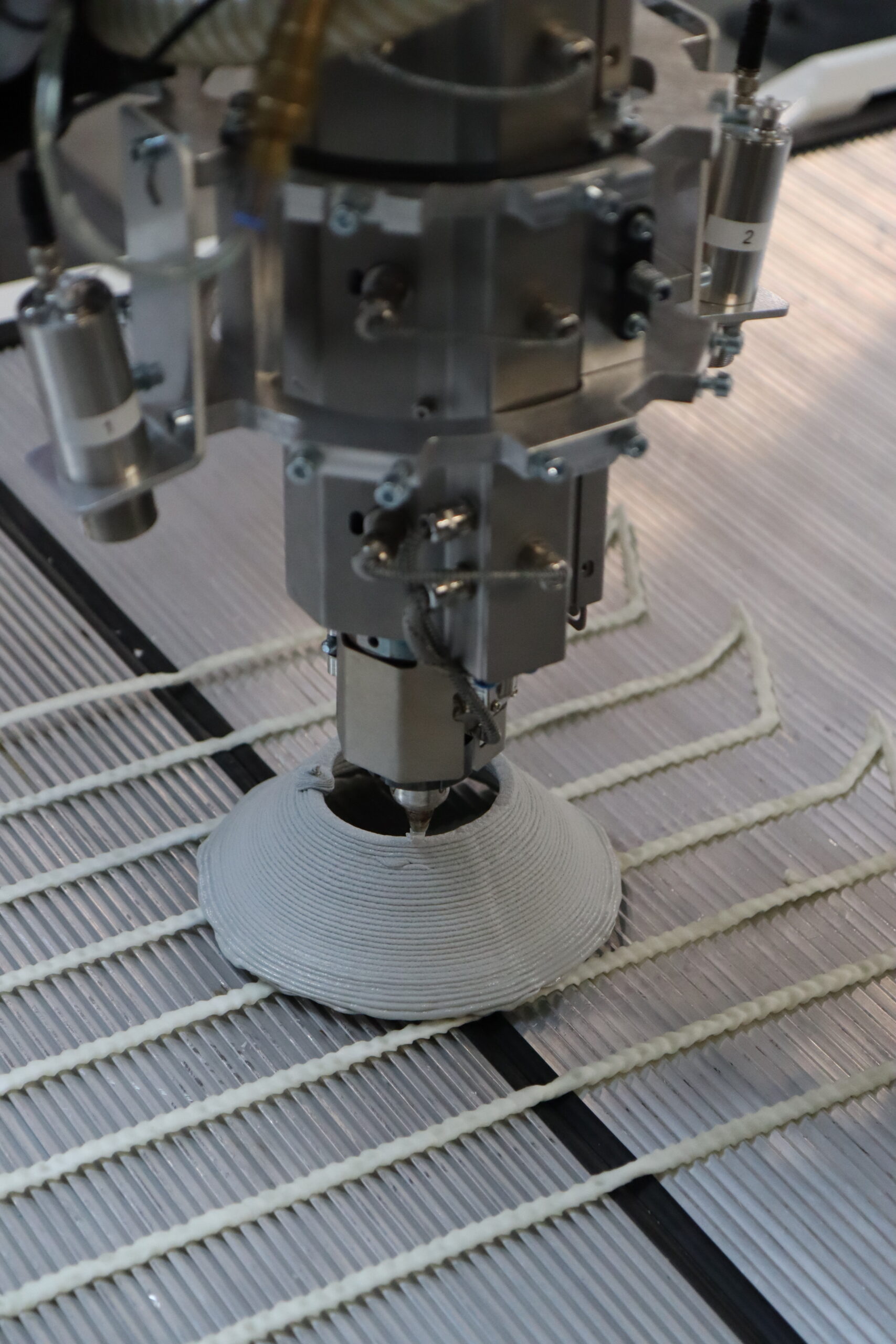

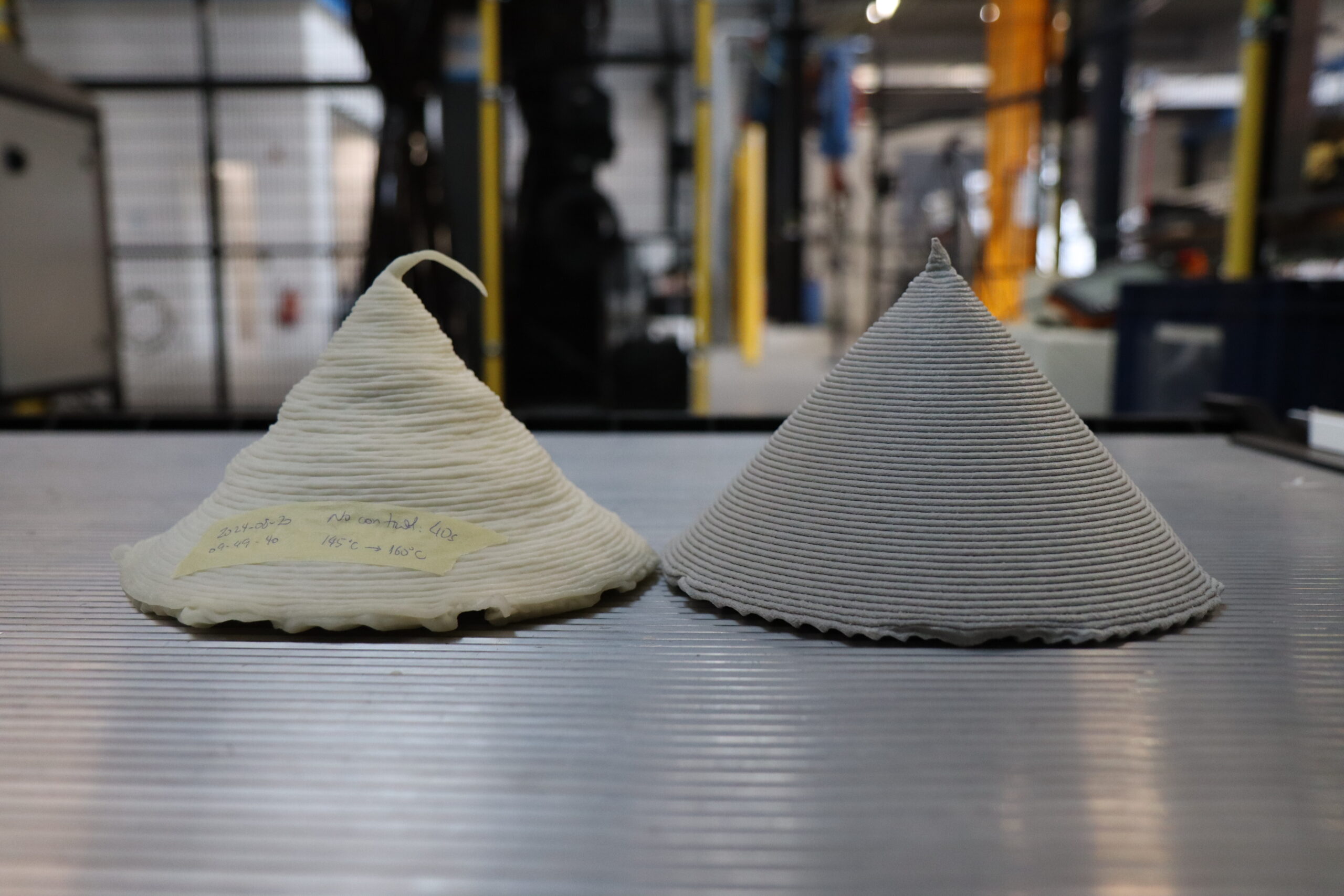

Gustavo Asai’s internship project at SAM XL focused on solving one of the crucial aspects of large-scale 3D printing: temperature control. If the previous layer gets too cold during printing, a new layer won’t bond properly – weakening the final product. Too hot, and the structure can warp under the weight of new material (see photo), resulting in a blob.

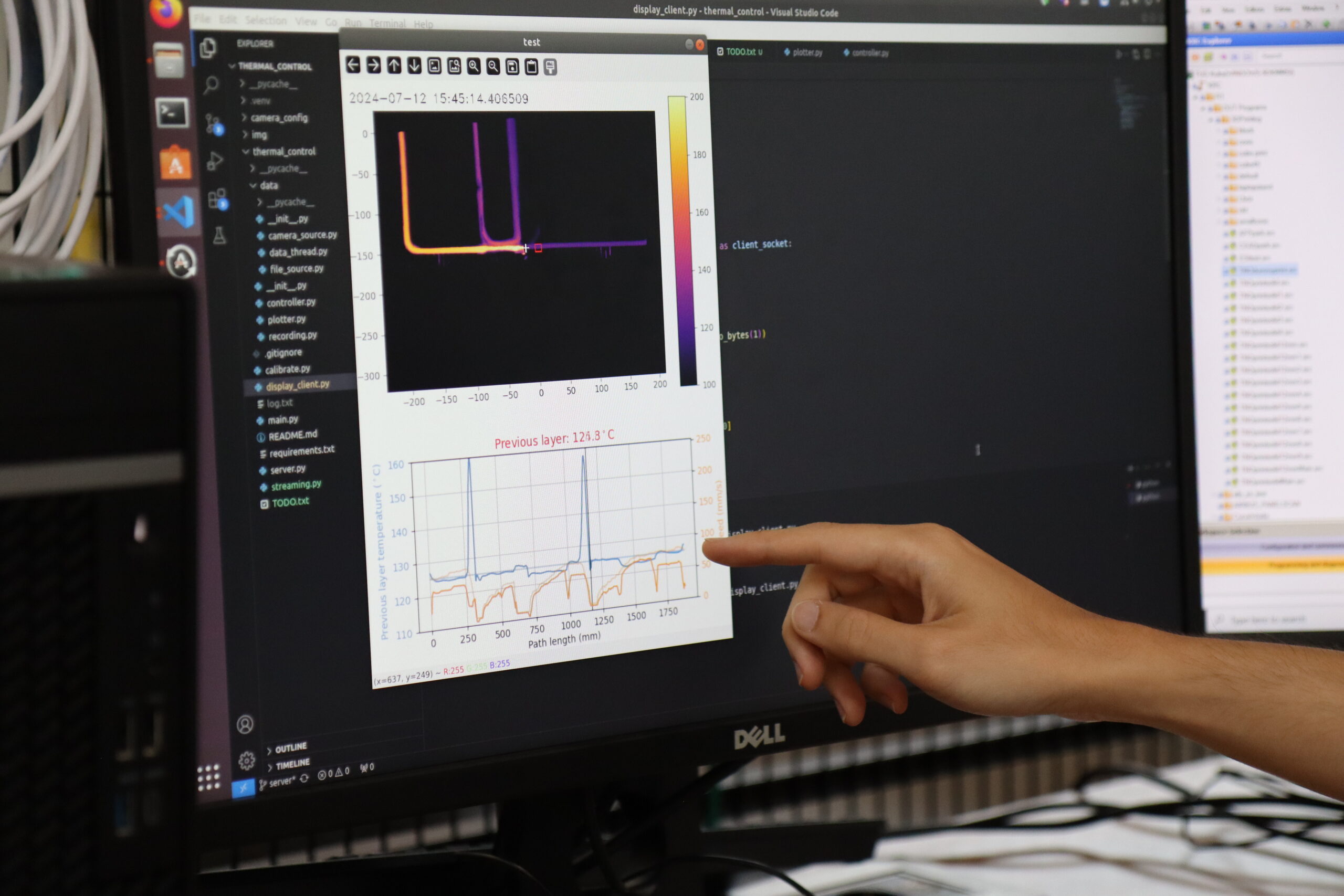

To solve this, Gustavo researched the key factors in the cooling process and developed a closed-loop controller. By using thermal cameras, his system continuously monitors the temperature and automatically adjusts the printing speed to ensure each layer is just right! Until now, you could only assess and adjust the printing process based on experience. With this control loop, we offer solid, real life quality monitoring. This saves a considerable amount of time and prevents material loss, which is crucial to expand the 3D-industry.

Gustavo’s supervisor Sungi Han is impressed by the results. Not only did Gustavo’s project make great strides in improving the quality of 3D-printed objects, but the data he gathered will also be used for developing thermodynamic models in future research.

Thank you, Gustavo Asai, for your hard work and dedication during your time at SAM XL, and good luck with your next challenge!