Mechatronics capabilities

Mechatronics forms an integral part in the creation of Smart Robotic Systems at SAM XL. Just like how mechatronics combines mechanical, electronic, control and computer systems, our mechatronic team is also multi-disciplinary by nature.

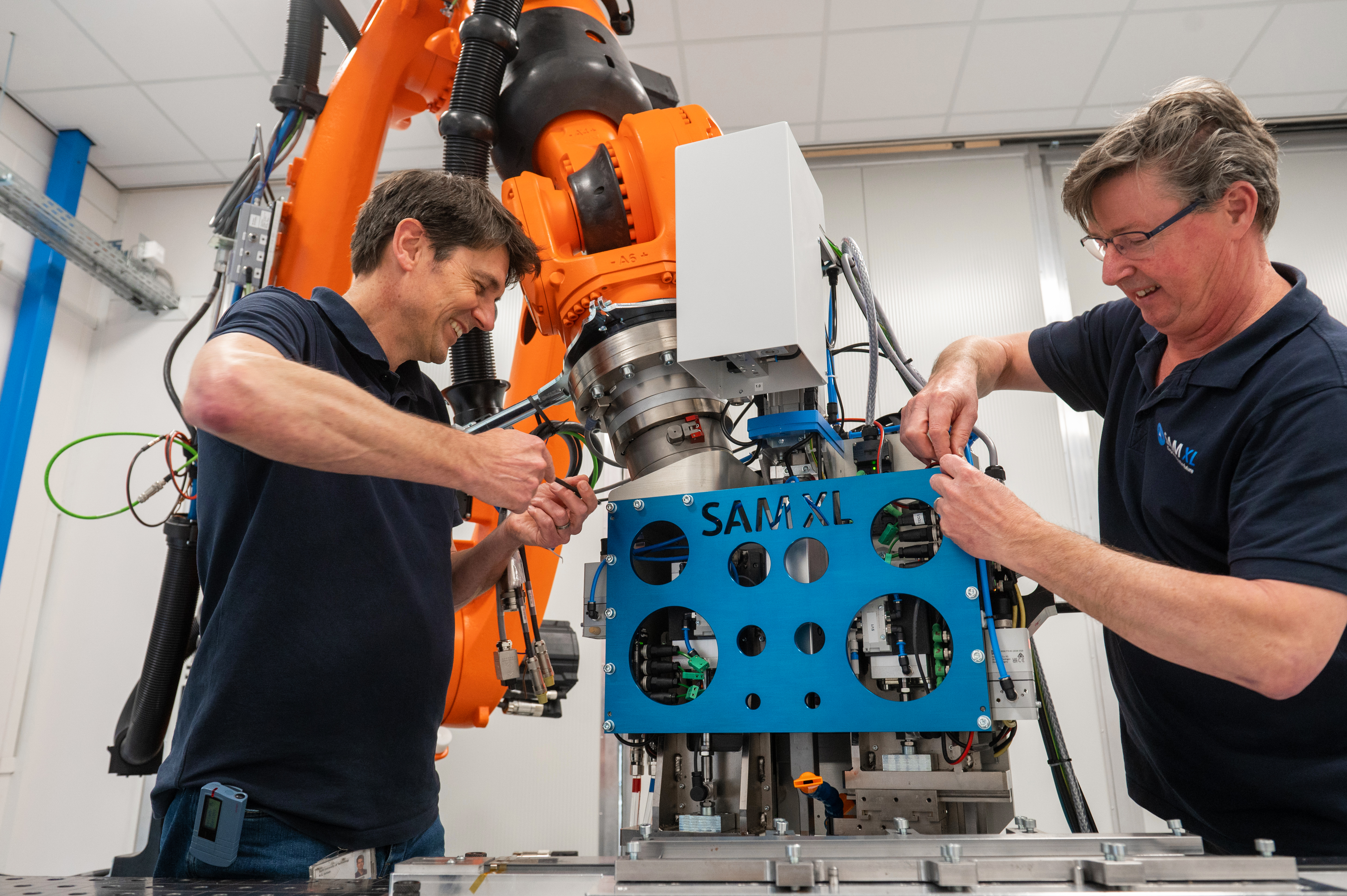

Robotic end-effector development

We design and produce customised end-effectors, and integrate them with our state-of-the-art robots into our smart robotics system. Tooling and production of prototypes can be done in-house at the DEMO workshop facilities of the TU Delft. PLCs with their dedicated drivers and electronic system boards are then used to integrate the three main parts of a robot: the controller, actuators and sensors. Together they form the physical backbone of our solutions.

A great example is our custom ultransonic welding end-effector (see photo), which opened up new possibilities for further research and development of this novel manufacturing process on an industrial scale. SAM XL is the perfect place for the development and maturing of such novel manufacturing processes due to our unique positioning between research and industry.

Mechanical testing

With our in-house expertise and unique infrastructure, we provide testbeds for mechanical testing to assess the structural, physical and mechanical characteristics of materials and products. By acquiring accurate, real-life data we determine the true mechanical properties of the material or assembly used in your product or project.

CAD

With our in-house CAD experts, we can develop our smart robotic systems from the early conceptual design phase onwards. We have a dedicated license in SolidWorks through which we develop and design our end-effectors and tooling in-house.

Outlook to the future

Mechatronics forms the connection between the advanced manufacturing technologies and the software needed to automate these together into a Smart Robotic system. In the smart manufacturing industry, it’s essential to be able to create your own hardware to quickly implement new solutions. In the coming years, SAM XL is determined to develop our mechatronic capabilities further to accelerate our innovative solutions towards industrial adoption.