About SAM XL:

Accelerator of innovation

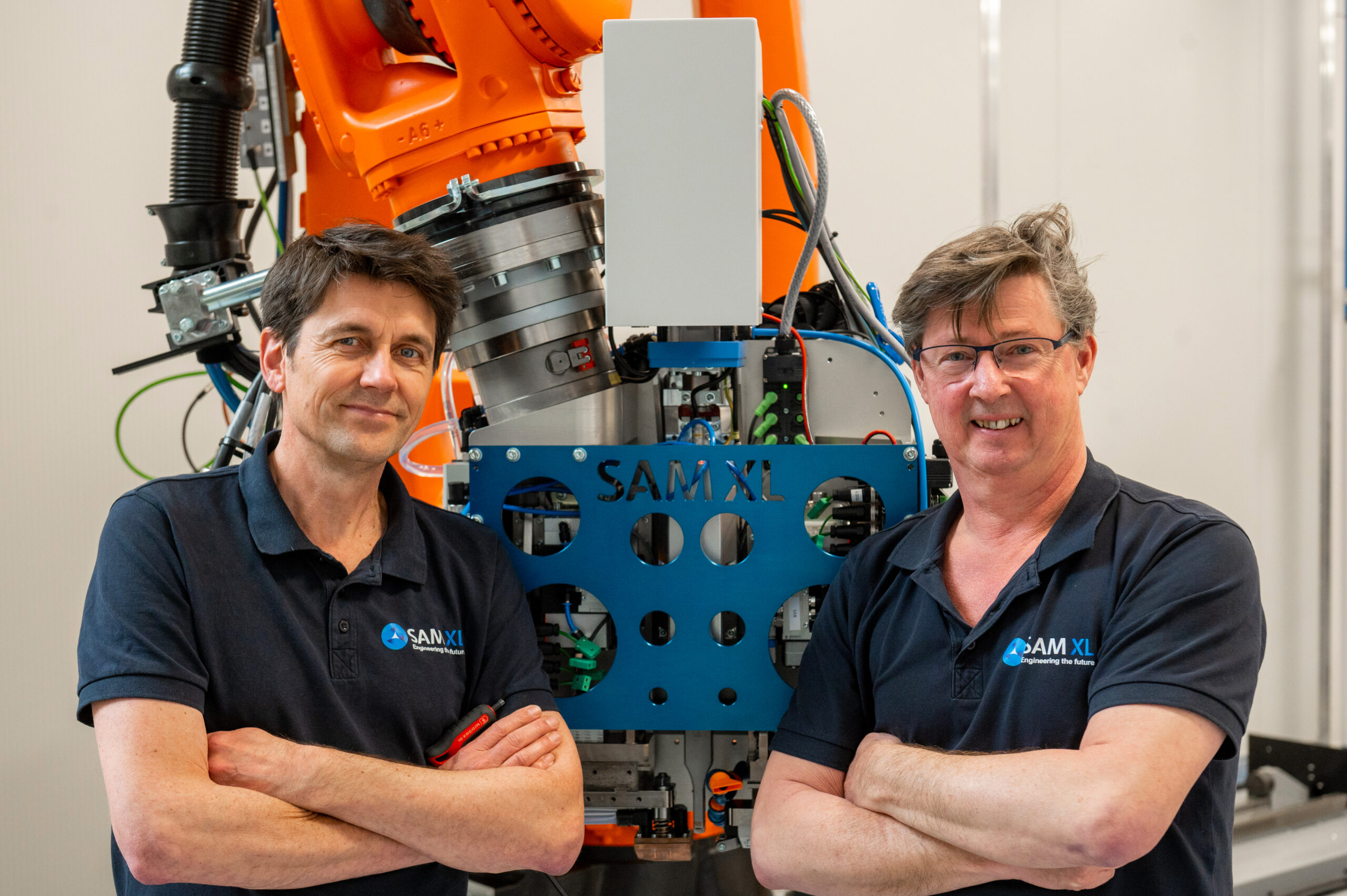

SAM XL was founded in 2018 as an expertise centre for Smart Advanced Manufacturing with the aid of XL robotics, hence our name: SAM XL. We maximize the synergy between skilled professionals and intelligent manufacturing systems. Our aim is to form the bridge between TU Delft scientists’ fundamental research and the industry’s needs. Our pragmatic approach to achieve this: small steps, big impact.

Facilities

SAM XL is located on the TU Delft campus, close to the Faculty of Aerospace Engineering. Our facility is a 2000 m2 research lab, with different robot cells and automation labs. SAM XL brings you at the centre of the vibrant Delft start-up community and the talented student body of Delft University of Technology, The Hague University of Applied Sciences and InHolland.

Robots

Our entire collection of robots is not only top of the range, but also capable of communicating with the outside world. They cover a wide range of payloads and ranges and all have the ability to output real-time data for monitoring purposes. Equipped with models and sensors capable of real-time, high-speed, path and task planning.

Ideally suitable for developing, demonstrating and validating Artificial Intelligence for the manufacturing industry. We use both the robot’s own programming software as well as the ROS industrial middleware platform to put our intelligent manufacturing systems into motion.

Team

Meet our dynamic team of highly skilled professionals! At SAM XL we are glad to collaborate with each other, with our TU Delft colleagues, with our partners and with our suppliers! Together, we are engineering the future. With aerospace technology in our DNA, we love to experiment, innovate and demonstrate.

Hein Koelman

CEO

Eveline van Kan

Business Controller

Claudia Kemper

Event and Office Manager

Heleen Woldhuis

Project Officer

Aashish Vatsyayan

Robotics Software Engineering Leader

Abhas Choudhary

Materials & Process Engineer

André Florindo

Automated Manufacturing Engineer

Antoine Dunand

Associate Engineer

Aydin van den Bergh

Business Developer

Berthil Grashof

System Integrator and Robot Safety Expert

Bram Jongbloed

Manufacturing & Automation Engineering Leader

Dave Kroezen

Robotics Software Engineering Leader

Emma Tobin

Automated Manufacturing Engineer

Eugenio Bernardi

Robotics Engineer

Johan van Stuyvesant Meijen

Associate Research Engineer

Joris Koopman

Tech Transfer Officer

Kate Twiss

Robotics Software Engineer

Maarten Bakker

Business Developer Civil Engineering

Martin Kampinga

Program manager

Menno Verkade

Education and Research Technician

Nadia Haïfi

Communications advisor

Nigel van Nierop

Associate Research Engineer

Nikhil Sethi

Robotics Software Engineer

Nithish Kumar

Robotics Software Engineer

Sungi Han

Additive Manufacturing Engineer

Syrine Zbidi

Software Automation Engineer

Thomas Hettasch

Robotics Software Engineer

Wouter Caarls

Senior Robotics Software Engineer

Interns & student assistants

Mickey Gielen

Assistant Communication

Richard Adam

Intern Software Engineer

Mathéo Maisonneuve

Intern Continuous Ultrasonic Welding

Board

Henri Werij

Board Chairman

Dean of Aerospace Engineering TU Delft

Stefan Aarninkhof

Board Secretary

Rinze Benedictus

Board Treasurer

Professor Aerospace Materials & Structural Integrity at TU Delft

Peter van Terwisga

Board Member

Director Research, Development & Innovation at Damen Naval

Anton Bakker

Board Member

Head of capabilities Technology Assembly & Metals GTC-NL at GKN

Technical Board

Rinze Benedictus

Technical Board Member

Professor Aerospace Materials & Structural Integrity at TU Delft

Gijs van der Hoorn

Technical Board Member

Researcher at the Delft Robotics Institute and the Delft BioRobotics Laboratory

Maarten Labordus

Technical Board Member

R&D Manager KVE Composites Group/Daher

Andy Francis

Technical Board Member

Technology Director at GKN

TU Delft experts

Nathan Eskue

AI for Manufacturing Certification

Clemens Dransfeld

Professor of Aerospace Manufacturing Technologies

Daniël Peeters

Assistant professor in aerospace structures & materials

Roger Groves

Associate Professor in Aerospace NDT/SHM

Martijn Wisse

Director of TU Delft Robotics Institute

Irene Fernandez Villegas

TU Delft thermoplastic composite welding expert

Our participants

Technology partners

Supporters & network

SAM XL is the outcome of the Composite Automation Development Program (CADC), which was funded via the European Fund of Regional Development (EFRD): a programme to build, use and grow a fieldlab for smart composite manufacturing technologies. The CADC consortium comprises of TU Delft, Fokker-GKN, Airborne, Airbus Defence & Space Netherlands, Suzlon, TNO, GTM Advanced Materials and KVE.