Yet another hackathon took place at SAM XL, this time, the teams had to build a robot to explore tunnels or pipe systems. Various solutions already exist in the industry for inspecting pipes for gas, water and sewage. But there is one thing these robots cannot do: climb vertical T-pieces. Therefore, the test setup with many vertical T-pieces presented a significant challenge for the teams. The pipe system contains inspection points, marked with a red line. The teams had to reach as many of these points as possible with their robot. In addition, they had to keep track of the location of the red markings. In order to do this, they had to keep track of their own coordinate system and figure out how to determine where everything was located in relation to this coordinate system.

The assignment is linked to BTScout. This SME carries out inspections of beaver and badger setts. Time is crucial in an environment where quick insight is required, such as under the railway. You need to know the extent of the problem, whether the sett is still inhabited, and whether filling is a suitable alternative to excavation. Through this hackathon, they are looking for inspiration and solutions for vertical climbing at tunnel intersections, and ways to accurately track their location.

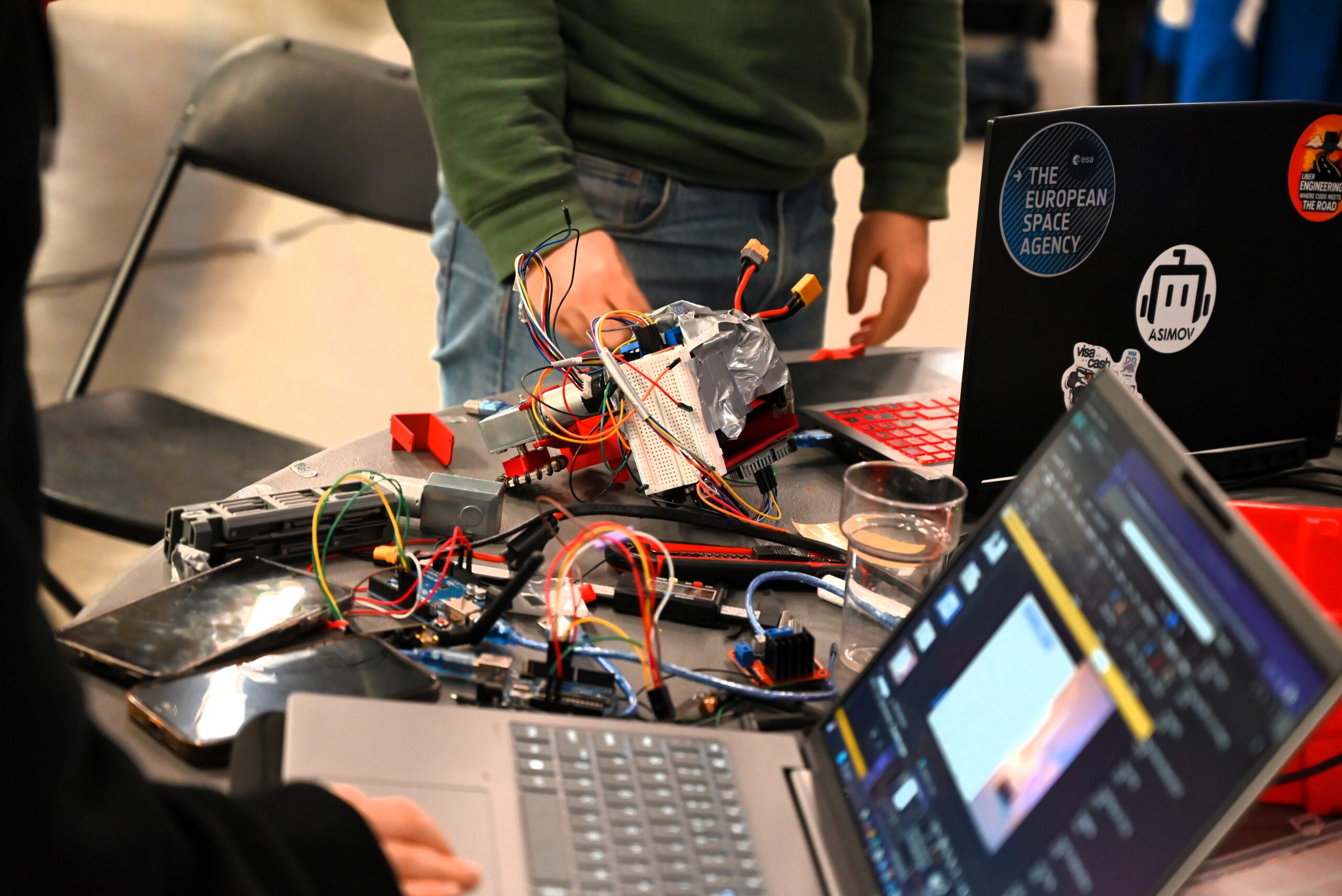

A total of 34 students from Delft University of Technology, De Haagse Hogeschool / The Hague University of Applied Sciences and Inholland University of Applied Sciences took part, forming six teams. During an intermediate competition, some teams had already demonstrated their ability to climb through a vertical tube. All teams performed excellently, and most importantly, they learned a great deal. The winning team, Team V4, is rightly proud of its victory.

Special thanks to Delft Robotics Student Association (RSA), our Education Lead Astrid van der Niet, our Education and Research Technician Menno Verkade, Edwin Kanters from InHolland and Mirjam Zijderveld from Haagse Hogeschool.