Sneak peek of our final deliverables in the PeneloPe EU project: a video of every partner’s achievements in the aerospace pilot line!

In the past two years, we have been developing a closed-loop, zero-defect manufacturing strategy for flexible and modular manufacturing. Together with partners GKN Fokker, KVE, TNO, K-LOOPS, Università degli Studi di Modena e Reggio Emilia and ESI Group we are collaborating within the large European consortium with a focus on large scale manufacturing techniques. We are currently processing the raw video footage of each partner, which will be combined into a compilation video of all processes.

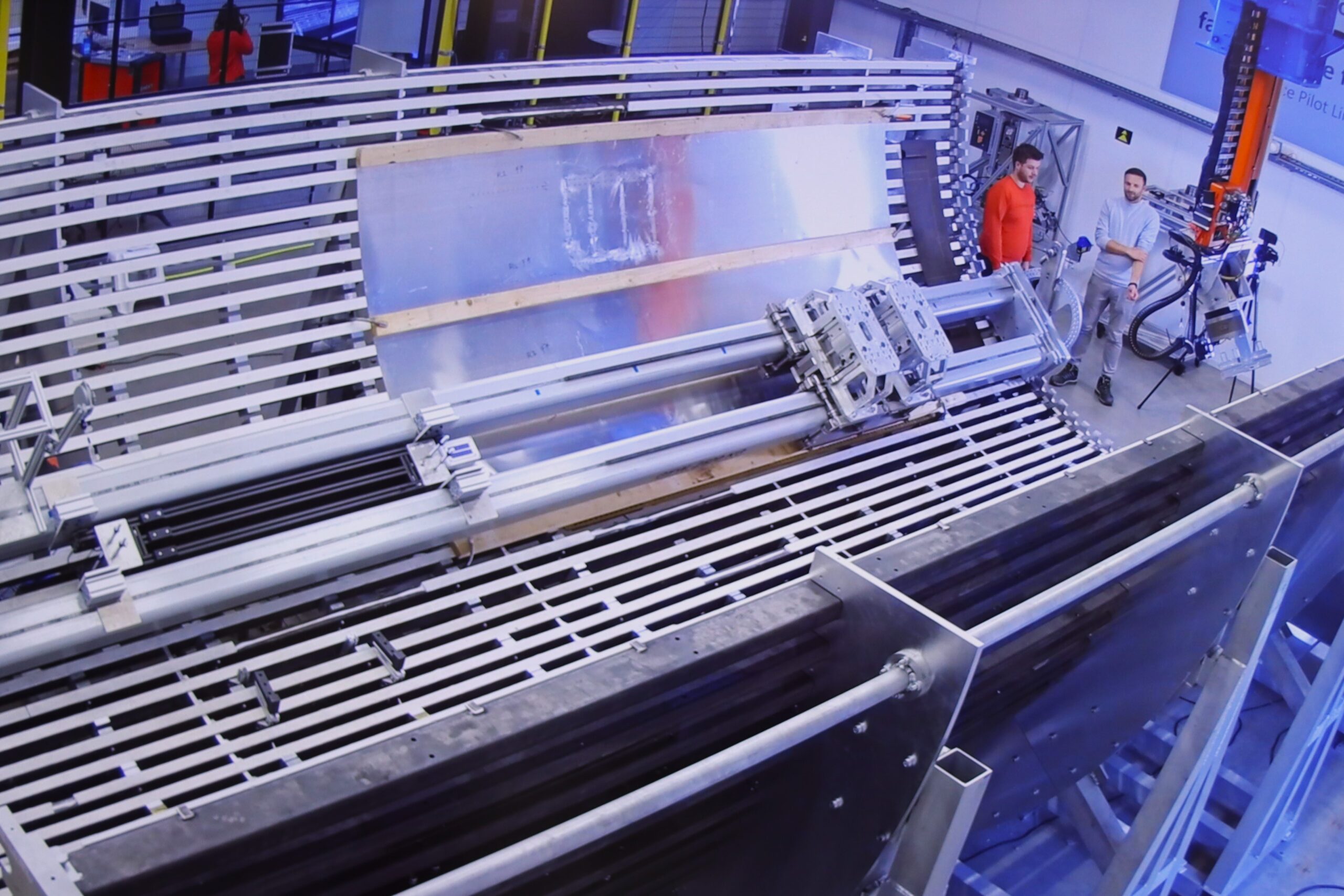

The SAM XL process you can see on the pictures, is aimed to reduce the overhead in programming new product variants in a production setting. Using sensors, the current shape and dimensions of the product are determined and used to generate robot trajectories. This approach allows us to generalize the production process to different parts and products.