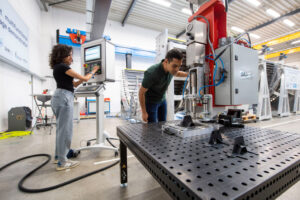

Manufacturing capabilities

We belong to the top leading research and technology organisations in advanced manufacturing technologies such as ultrasonic welding, additive manufacturing and inspection. Together with our partners, we co-develop these techniques towards full-scale implementation by the industry.

Ultrasonic welding of thermoplastic composites

SAM XL has a unique solution for the continuous ultrasonic welding of thermoplastics. Combined with a patented sonotrode, SAM XL is pushing the boundaries when compared to other welding technologies for thermoplastics. Our state of the art technology will enable the adoption of these lightweight materials in, for example, the Aerospace and Automotive industry.

Automated fibre placement

Automated fibre placement is used to make complex composite parts (see video). More specifically, SAM XL will be one of the very few centres in Europe where thermoplastic automated fibre placement can be done with a powerful Humm3 flashlamp system.

An example application of this technology is the development of a lightweight thermoplastic composite hydrogen tank, resistant to the low temperature of liquid hydrogen. Liquid hydrogen (LH2) is increasingly seen as a viable alternative fuel to meet our global sustainability goals in aviation and shipping. Currently, tanks are not able to sustain 100+ cycles and often made from metals – which is less weight efficient. Therefore, the development of weight efficient and long-life storage solutions is crucial. To achieve this the SAM XL team is working on automation techniques, welding techniques and assembly of a LH2 tank demonstrator segment. Check out the video below

3D printing

SAM XL has a unique approach towards 3D printing. By making use of thermal mechanical models and the senor systems on our robot, a closed-loop process control on our robotic 3D printing is enabled. This allows to greatly increase the quality of 3D printing with much less waste. For our internal R&D we will use our 3D printing solutions to make moulds for our automated fibre placement line.

Inspection

With typical non-distructive testing (NDT) processes such as laser line scanning and ultrasonics, we are developing static and dynamic mobile inspection stations to automate typical quality control processes that are relevant for our industrial partners.

Outlook to the future

In the coming years we will continue to expand our expertise on advanced manufacturing technology and maintenance and repair, including subtractive manufacturing. As a leading institute in continuous ultrasonic welding and thermoplastic automated fibre placement for sustainable aviation, we continue to explore other industry segments and other manufacturing processes.