An important moment for our research centre as we upscale our ultrasonic welding capabilities. With the installation of our brand new, in-house developed end effector, we are one step closer to bringing the welding technology to an industrial scale.

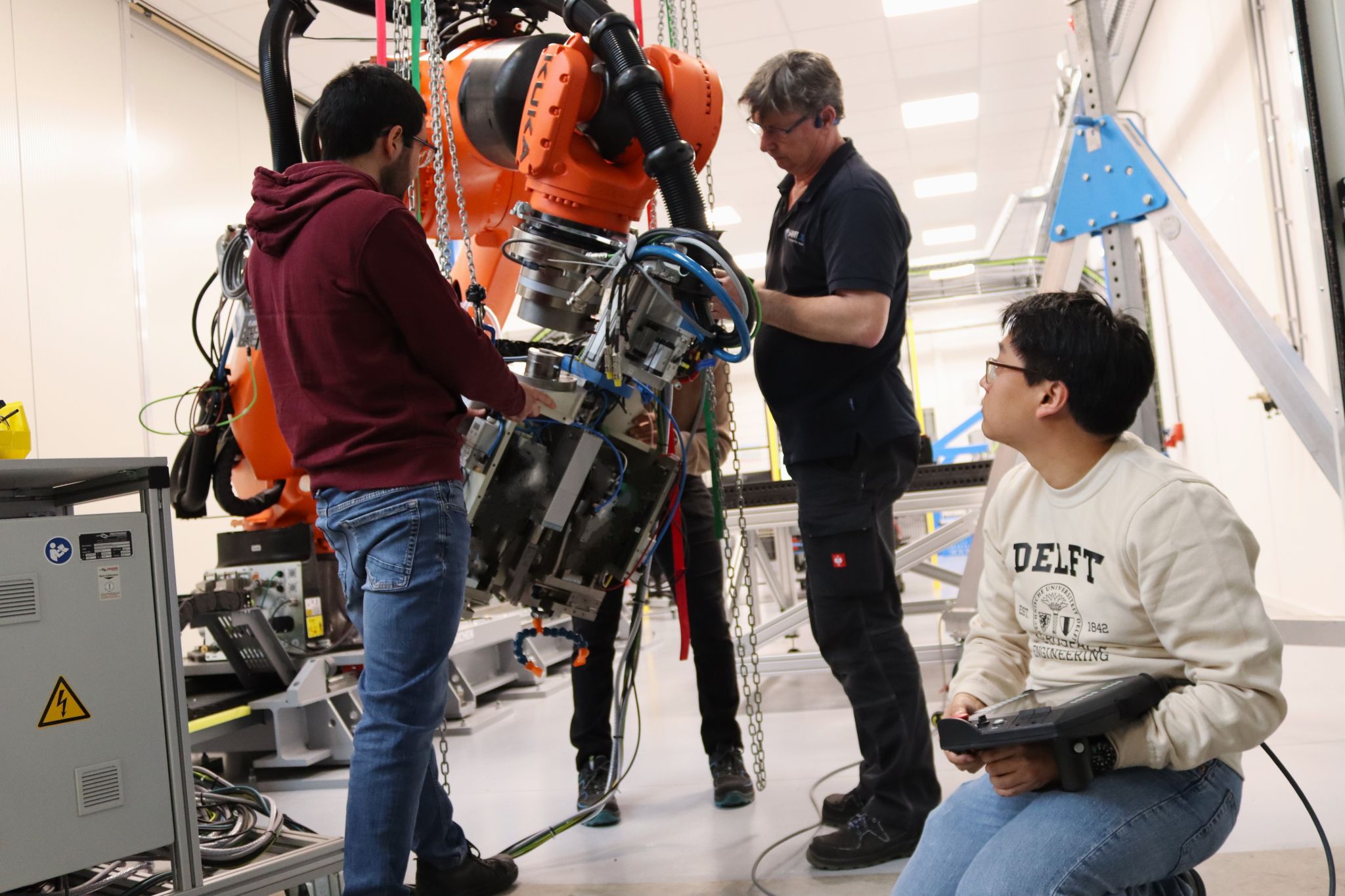

Menno Verkade, Berthil Grashof, Sungi Han and André Florindo worked together to design, build and integrate the end effector. This project is a good example of smooth collaboration between engineers with different backgrounds and expertise, bringing together mechanical design, mechatronics, software, automation, robotics and process engineering.

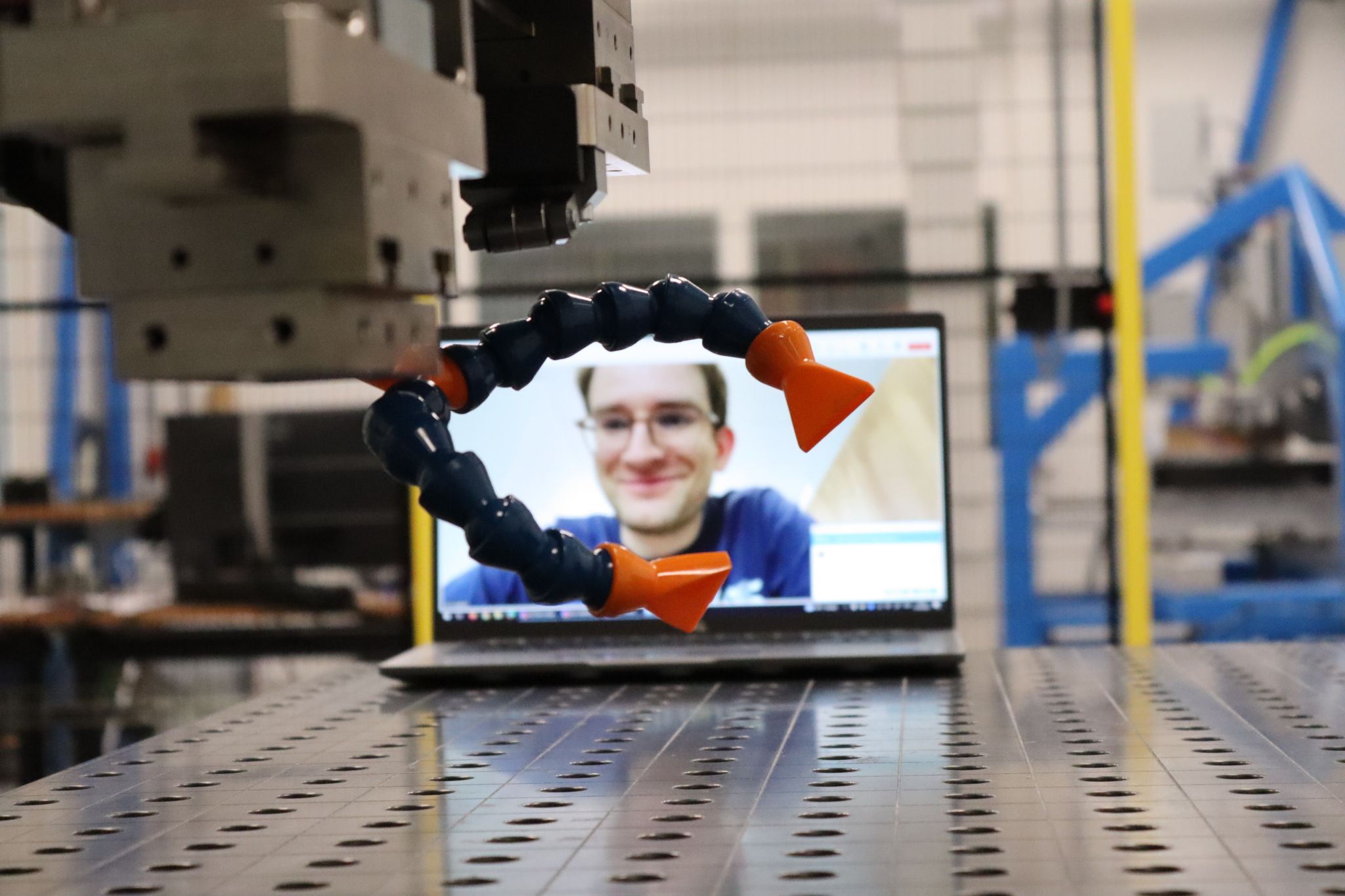

Bram Jongbloed, who is leading the development of SAM XL’s continuous ultrasonic welding process, was delighted to be able to join in online to witness this team effort:

“We have achieved high-quality, stable welds on a smaller scale. Our new welding end effector opens the possibility for further research and development of this technology on an industrial scale. We aim to make a wide range of applications possible for lighter aircraft. Our collective motivation is to work towards sustainable aviation, together as a team and with our top tech partners”.