Software capabilities

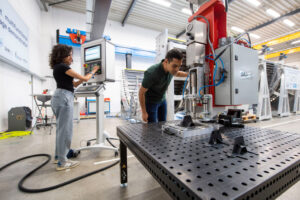

We develop our own robotic automation software. We make robots smarter, more accurate and more efficient and demonstrate our software on automation challenges, within the industrial use cases of our partners. In this way, we are speeding up innovations for new proof-of-concepts to be adopted by the industry.

Advanced motion planning

The algorithms that our experts develop, allow a robot to autonomously program its own movement and trajectories, while keeping safety aspects such as collision into account, without the need for an operator to do the manual programming for every new path or motion. This novel approach to motion planning combined with object reconstruction allows to perform highly optimized “Scan&Plan” operations which are very relevant in the large manufacturing industries.

Zero Programming

Zero Programming refers to the user not having to program or edit any robot programs when introducing new product variants in an automated process. Instead of hard-coding fixed robot programs (or by extension scripts to generate the fixed robot programs), the tool paths and robot trajectories are generated based on the actual geometry and location of the product. Main benefits include: flexible placement of object relative to the manipulator and an independence of the variations of the product, e.g. in length, width, or feature locations.

Perception

With our computer vision expertise, our automation toolbox has packages to perform accurate, real-time and 3D object reconstruction and registration. This allows to ‘see’ where tools and parts are located without the need for an operator to manually measure and/or register parts.

Closed-loop process control

Closed-loop process control is the way towards smart robot autonomation: it will allow the robot to perceive the reality as it is. By measuring real physical parameters, comparison with digital models can be made that allow the robot to perform in-situ corrections. Ultimately this leads to a new form of automation where the robot basically programs itself: autonomation using SAM XL expertise.

Outlook to the future

Introducing AI and machine learning into smart robotic systems will increase the robustness of our closed-loop process control capabilities. Our solutions will become more flexible and adaptive in their application. This is essential for the cost effectiveness of automation in low volume, high variation manufacturing and maintenance processes.