During ITHEC, the International Conference and Exhibition on Thermoplastic Composites, SAM XL won the ‘best technical poster voting’.

Abhas Choudhary and Bram Jongbloed represented SAM XL at the conference.

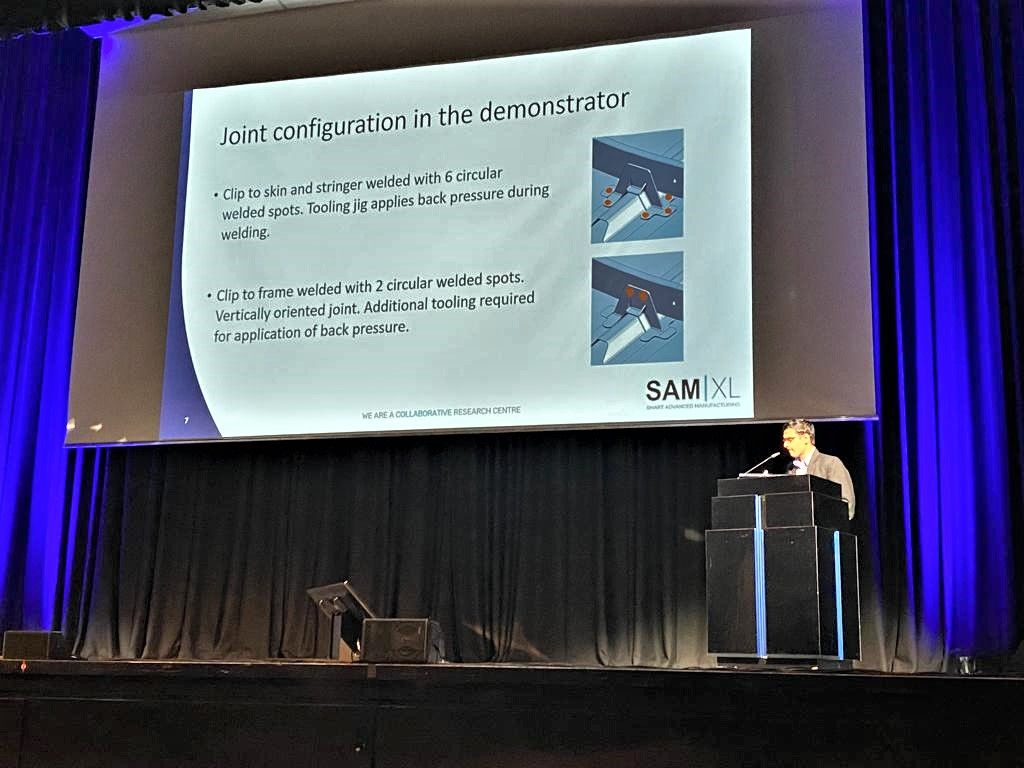

STUNNING project lead Abhas presented our approach in applying several complicated innovative ultrasonic welding techniques for the sub-assembly of one of the world’s largest thermoplastic composite structures. He zoomed in on automated ultrasonic spot welding which we applied to the lower shell of the multifunctional fuselage demonstrator located at SAM XL.

“There was a lot of interest in the automation solutions that we created, due to the meticulous technology development and de-risking activities performed at SAM XL in preparation for the automated sub-assembly of the demonstrator. Our expertise proved valuable to others in the industry, as we received many in-depth questions.

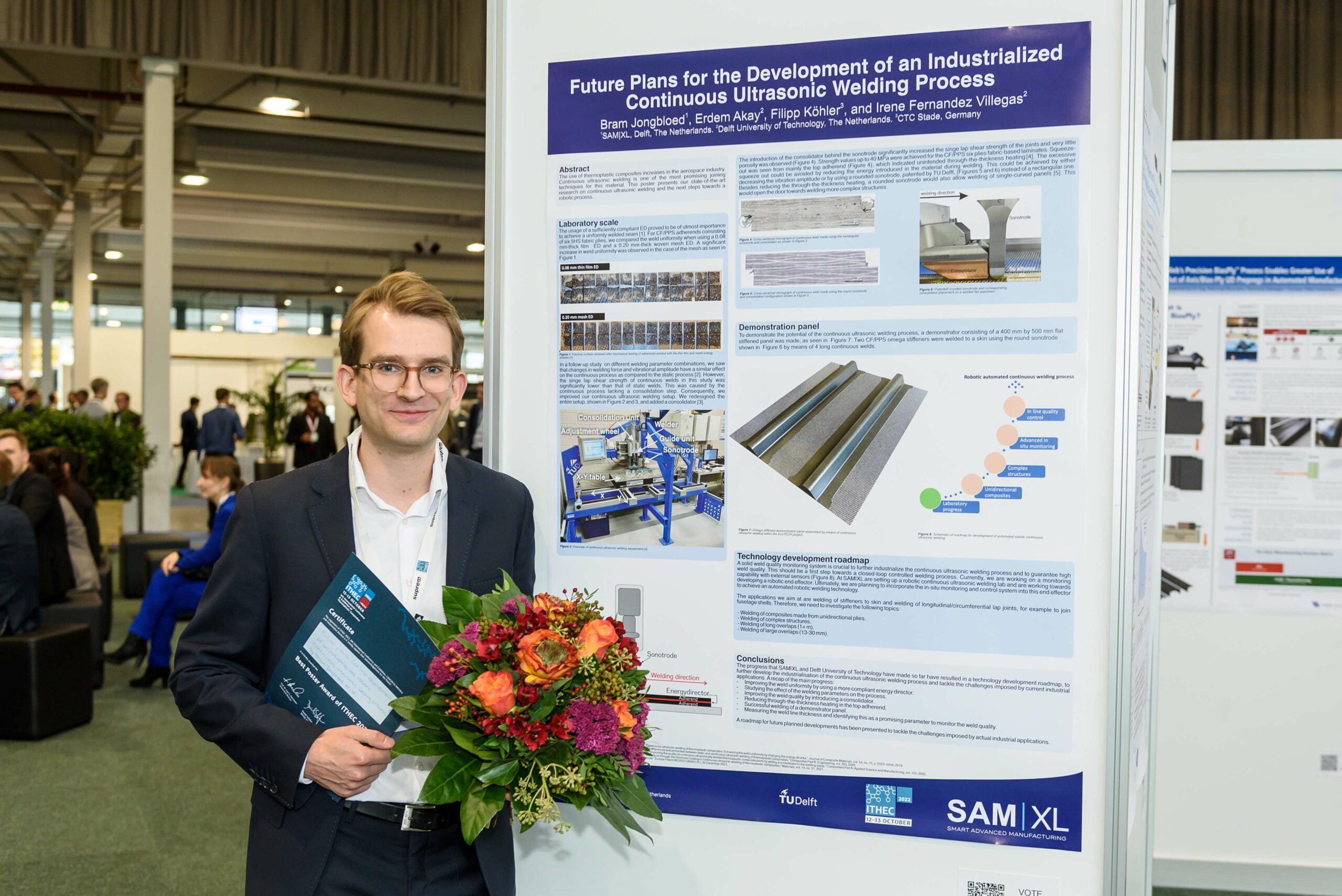

Bram Jongbloed’s technical poster lays out the development process and our future steps towards an industrialized continuous ultrasonic welding process. As a materials and process engineer, Bram was thrilled that his poster was voted best out of 19 posters in total.

“It was rewarding to get feedback from the attendees that we succeeded in clarifying our achievements, findings and challenges in this complicated process. This research is developed and tested in our own facility at TU Delft Campus. We have ambitious plans to create a robotic automated continuous welding process. We all see the potential and relevance for an industrial scale, as material manufacturers and R&D companies have challenges in automation. SAM XL is aiming to tackle this”.

In order to achieve this, the next steps in the research will be:

- Welding of composites made from unidirectional plies

- Welding of complex structures

- Advanced in situ monitoring

- Ensure it is in line with quality control.

Want to know more about our continuous welding techniques and other SAM XL innovations? Stay tuned to our LinkedIn page.